NDT

NDT Course

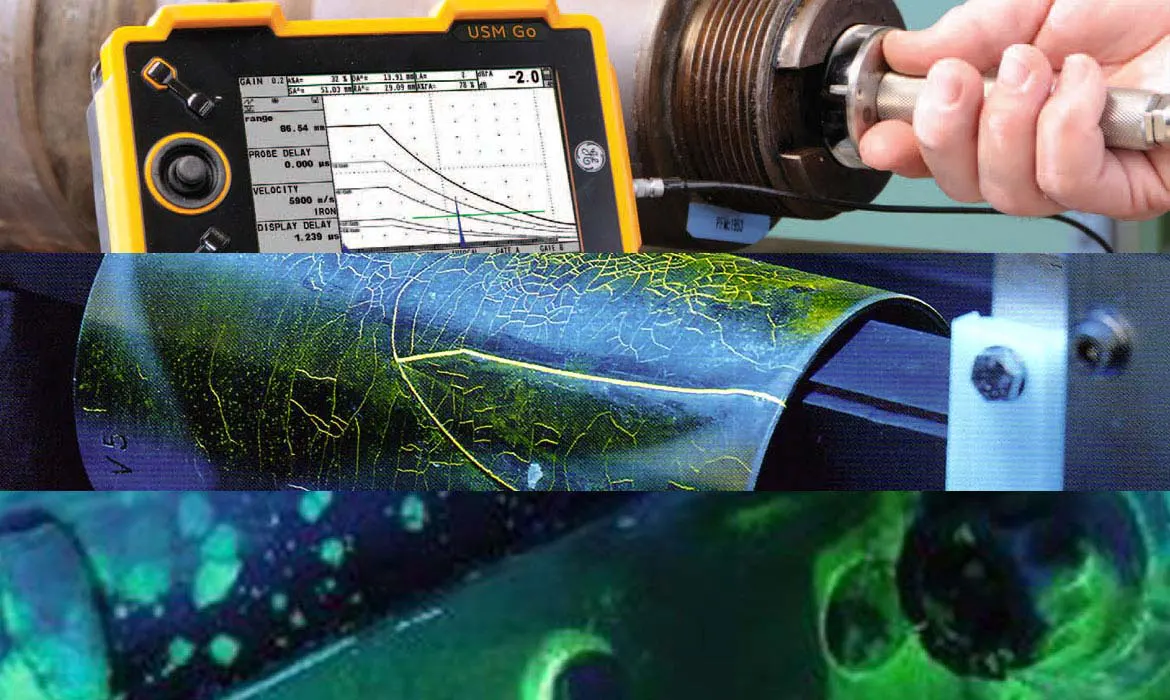

NDT is a field of engineering encompassing the testing and inspection of materials and equipment to evaluate condition, find flaws and defects, and extend the useful life of the infrastructure all around us. The use of noninvasive techniques to determine the integrity of a material, component or structure or quantitatively measure some characteristic of an object. i.e. Inspect or measure without doing harm.

Course Objectives

- Definition of NDT

- Methods of NDT

- What are Some Uses of NDE Methods?

- When are NDE Methods Used?

- Six Most Common NDT Methods

- Visual Inspection

- Liquid Penetrant Inspection

- Magnetic Particle Inspection

- Magnetic Particle Crack Indications

- Radiography

- Film Radiography

- Eddy Current Testing

- Ultrasonic Inspection (Pulse-Echo)

- Common Application of NDT

- Inspection of Raw Products

- Inspection For In-Service Damage

- Power Plant Inspection

- Wire Rope Inspection

- Storage Tank Inspection

- Aircraft Inspection

- Jet Engine Inspection

- Pressure Vessel Inspection

- Rail Inspection

- Bridge Inspection

- Pipeline Inspection

- Special Measurements

- Radiographic standards for evaluation of weld defects

- Iiw radiographic standards for evaluation of weld defects.

- Radiographic standards for evaluation of cast defects.

- NON DESTRUCTIVE TESTINING TRAINING COURSES :

- 1. 1 Ultrasonic Testing (Level-1), (Level-2), (Level-3)

- 2. 1 Radiography Testing (Level-1), (Level-2), (Level-3)

- 3. 1 Magnetic Particle Testing (Level-1), (Level-2), (Level-3)

- 4. 1 Liquid Penetrant Testing (Level-1), (Level-2), (Level-3)

- 5. 1 Visual Testing (Level-1), (Level-2), (Level-3)

- 6. Radiography Film Interpretation

- 7. Eddy Current Testing (Level-1)

- 8. Eddy Current Testing (Level-1)

- 9. ISO 9001 Internal Auditor

- 10. NADCAP Certification internal training (NAS -410 , Level 1&2 certification) & Pre-audit Preparation.

Non-Destructive Testing (QA/QC) Training Course

Quality Assurance (QA) suggests as a set of procedures that ensure that product-undergoing development can fulfill the requirements of customer and clients whereas Quality Control (QC) is a set of methods that provide that a manufacturing product can meet the needs of the customer. Non-Destructive Testing which is a group of analysis techniques which exists for testing, inspecting, evaluating materials, or assemblies for the difference in factors which cause any damage to the test material

Course Objectives

- Review quality of materials with all project specifications.

- Radiographic testing

- Magnetic particle testing

- Ultrasonic testing

- Liquid penetrant testing

- Visual testing

- Welding inspection devices.

Eligibility

- 10th / HSC / Bsc / Diploma.

- BE/ BTECH from Mechanical/ Production or Automobile Engineering.

- M.E.