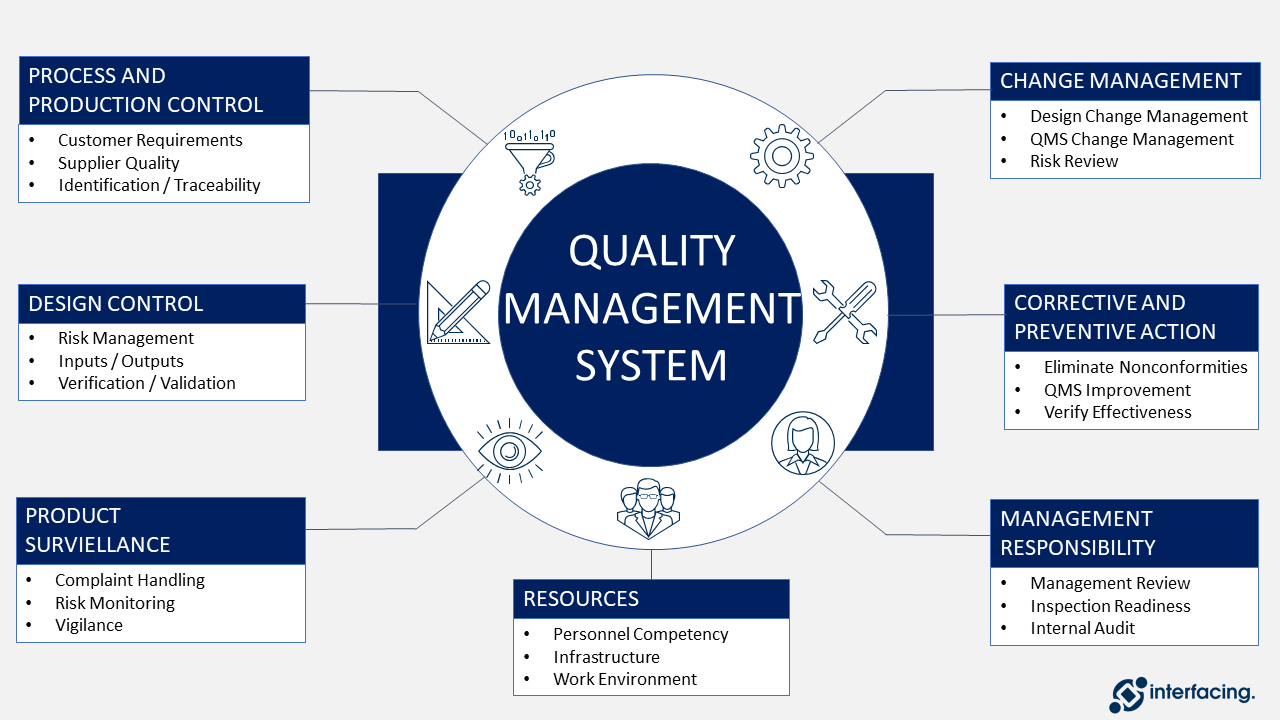

Quality Management System

ISO 9001:2015 Internal Auditor Course

Internal auditing of Quality Management System is a process that assesses the level of implementation and thus has become a great tool for improvement. This internal auditor course will be a blend of training sessions, exercises and group discussions coupled with learning to achieve its objectives.

Your Benefits:

- Participate will be able,

- 1. To understand the roles and responsibilities of an internal auditor

- 2. To plan, conduct and report the audit

- 3. To understand the interpretation of ISO 9001:2015 standard.

- 4. Gain the skills to assess an organiza- tion’s capability to manage its QMS

Exam Details:

-

Written examination (open book) during the course.

Minimum passing criteria: 60%.

Certification:

- Participants who scores 60% and above in the written examination will be issued a internal auditor certificate. Unsuccessful candidates will be issued a certificate of attendance.

Course Content / Outline:

-

1. Quality Management System Requirements – Context, Leadership,

Support, Operation, Performance & Improvement - 2. Auditing principles

- 3. Roles and responsibility of auditors

- 4. Planning an internal audit

- 5. Conducting an audit

- 6. Reporting audit results

- This course is designed for:

- 1. Top management

- 2. QMS managers and officers

- 3. QMS internal auditors

- 4. Anyone interested in Quality management system

- 5. Anyone involved in the auditing, maintaining or supervising of an ISO 9001:2015 QMS

Who Should Attend?

Training Duration:

- 2 Days.

Eligibility

- Have basic knowledge and understanding of Quality Management System.

- ISO 9001:2015 will be an added advantage.

IATF 16949:2016 Internal Auditor Course

This course is designed for new internal auditors and experienced internal auditors who need to perform internal quality audits to IATF 16949:2016. Participants will complete an in-depth review of ISO 9001:2015, IATF 16949:2016 and the tools to effectively prepare and conduct internal audits. This internal auditor course will be a blend of training sessions, exercises and group discussions coupled with learning to achieve its objectives.

Your Benefits:

- Participate will be able,

- 1. To understand the roles and responsibilities of an internal auditor

- 2. To plan, conduct and report the audit

- 3. To understand the interpretation of ISO 9001:2015 standard.

- 4. Gain the skills to assess an organiza- tion’s capability to manage its QMS

Exam Details:

-

Written examination (open book) during the course.

Minimum passing criteria: 60%.

Certification:

- Participants who scores 60% and above in the written examination will be issued a internal auditor certificate. Unsuccessful candidates will be issued a certificate of attendance.

Course Content / Outline:

- 1. Identify linkages to quality management principles.

-

2. Demonstrate an understanding of and apply the automotive

process approach to auditing, including risk-based thinking. -

3. Demonstrate an understanding of ISO 9001:2015 and IATF

16949:2016 -

4. Identify the requirements applicable to an IATF 16949:2016

internal auditor -

5. Identify linkages between IATF 16949:2016 requirements and

Customer Specific

- This course is designed for:

- 1. Quality executives/managers in Automotive Supply Chain (and also from non-automotive, if interested),

- 2. Management representatives

- 3. QMS Consultants

- 4.Personnel wishing to attend higher level courses such as Lead Auditor courses.

Who Should Attend?

Training Duration:

- 3 Days.

Eligibility

- Basic knowledge of the ISO 9001:2015

- Customer Specific Requirements and the Core Tools.

LEAN SIX SIGMA

To improve business performance, two different methodologies of Lean and Six Sigma are amalgamated to form Lean Six Sigma. A management approach, application of which enhances quality and efficiency when effectively implemented, Lean Six Sigma training provides a structured approach to resolve any organizational problems, thereby improving the holistic performance. Six Sigma is a set of practices, used to systematically improve processes by eliminating defects. A defect can be failure of a product, process, or service, in meeting the requirements of internal or external customers. Since it was first introduced by Motorola in manufacturing, no industry has remained untouched by the benefits of Six Sigma.

On one hand the focus of Lean is across efficiency, speed, and to eliminate waste out of the process. Six Sigma on the other hand lays emphasis on effectiveness and the process of removing any organizational errors. Together, Lean Six Sigma Certification provides a toolkit and a systematic approach to help organizations and their employees have the requisite problem solving skills. In short, the approach builds a problem-solving culture by using the best methods to help organizations and institutions achieve their targets while satisfying their customers.

Your Benefits:

- Lean Six Sigma training and certification helps large organizations become more robust and ensures small organizations become nimbler. In simple words, the Lean Six Sigma certification helps businesses create a roadmap that will help them effectively meet their strategic goals. It also helps businesses reduce costs by freeing up resources, increases revenue, and adds value at places the organization needs them the most.

Exam Details:

-

Written examination (open book) during the course.

Minimum passing criteria: 60%.

Certification:

- Participants who scores 60% and above in the written examination will be issued a internal auditor certificate. Unsuccessful candidates will be issued a certificate of attendance.

Course Content / Outline:

- 1.0.DEFINE

- 1.1 Six Sigma Overview

- 1.2 The Fundamentals of Six Sign

- 1.3 Lean Six Sigma projects

- 1.4 Lean Fundamentals

- 2.0 MEASURE

- 2.1 Process Definition

- 2.2 Six Sigma Statistics

- 2.3 Measurement System Analysis

- 2.4 Process Capability

- 3.0 ANALYZE

- 3.1 Inferential Statistics

- 3.2 Hypothesis Testing

- 3.3 Hypothesis Testing : Normal Data

- 3.4 Hyp Testing : Non-Normal Data

- 4.0 IMPROVE

- 4.1 Simple Linear Regression

- 4.2 Multiple Regression Analysis

- 5.0 CONTROL

- 5.1 Lean Control

- 5.2 Statistical Process Control

- 5.3 Six Sigma Control Plans

Training Duration:

* 60 Hours.

What Students Are Saying

Hi I am Sanjivani , working in purchase department .

It was really a great experience after attending IATF 16949:2016 Internal Auditor training . I am now more competent and confident in structuring, planning and undertaking internal system in my organization . It’s a Booster Dose to move myself and my organization towards successful and powerful Empowerment

Thank Cadline Infotech.

Sanjivani

Hi I am Abhijeet,

precise notes which helped in understanding the concepts more easier. Focuses on basic so advance concept looks easier. Very simply & smooth doubt solving . Perfect explaining small concept for understanding every step of knowledge. Vey good experience with cadline infotech.

Thanks to Cadline Infotech.

Abhijeet

Hi I am Sudarshan,

A wonderfully practical course – both personally and professionally. Thank You Sir for all the inputs. Good to be updated on the changes that have taken place. Top marks for the instructor. Overall the course is going to be very useful in my day to day job. Thanks to Cadline Infotech.

Sudarshan

Hi I am Ajay Sharma, R & D Head (Fastener Industry)

It was a great experience after the training of IATF 16949 awareness and internal auditor training.

Understood more about the clauses interpretation and QMS processes . I am now more confident and competent in our organization process and QMS

Thanks to Cadline Infotech